| Material # |

Density (g/cm3) |

Elastic modulus (Gpa) |

Tensile strength (Mpa) |

Yield strength (Mpa) |

Thermal conductivity (W/mK) |

Thermal expansion

(10-6/℃) |

Elongation (%) |

Hardness (HB) |

| 2009/SiC/15p | 2.78 | 96 | 250 | 120 | 138 | 18.5 | 10 | 68 |

|

2009/SiC/20p |

2.80 | 103 | 270 | 140 | 146 | 17.4 | 9 | 72 |

|

2009/SiC/25p |

2.88 | 115 | 280 | 150 | 150 | 16.1 | 8 | 90 |

|

6061/SiC/15p |

2.74 | 95 | 240 | 116 | 140 | 18.4 | 9 | 66 |

|

6061/SiC/20p |

2.80 | 103 | 265 | 132 | 150 | 17 | 8 | 70 |

|

6061/SiC/25p |

2.84 | 121 | 274 | 136 | 146 | 15.8 | 7 | 84 |

|

6061/SiC/40p |

2.90 | 140 | 285 | 183 | 130 | 13 | 4 | 98 |

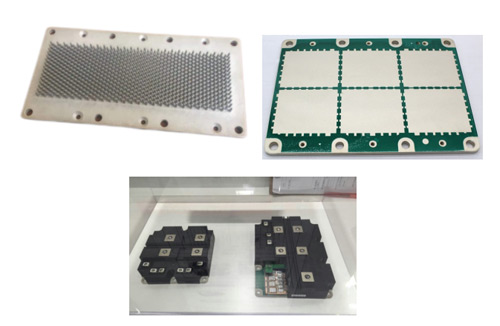

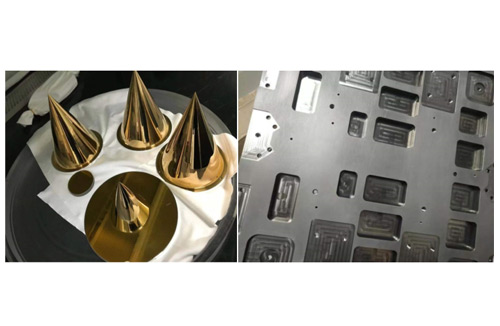

With its lightweight, efficient dynamic response and maximized life cycle, AlSiC can replace titanium alloy, steel and carbon fiber composite materials on a variety of precision instruments.

◆AlSiC structures are light weight and have high strength and stiffness, and low thermal expansion.

◆AlSiC parts can be net shaped or near net shaped on complex structures

◆AlSiC structural parts can be inlaid with other materials (titanium alloy, stainless steel, Kovar alloy, etc. or other intolerant non-metals)

◆AlSiC surface can be mirror-finished after vapor deposition

◆The surface can be plated with nickel, gold, silver, copper with good plating performance.

Application: AlSiC can be used in heat-resistant deformation structural parts, wear-resistant structural parts, lightweight aviation, aerospace structural parts, ball mounter and robots.