| Material | Density(g/cm3) | Thermal Expansion(CTE ppm/℃) | Thermal Conductivity(W/mK) | Unit Stiffness (GPa*cc/g) |

| AISiC | 2.95-3.05 | 6-9 | 180-240 | 39-105 |

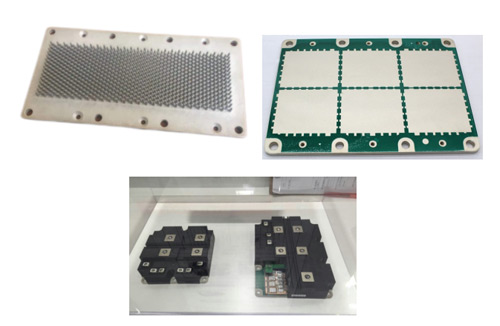

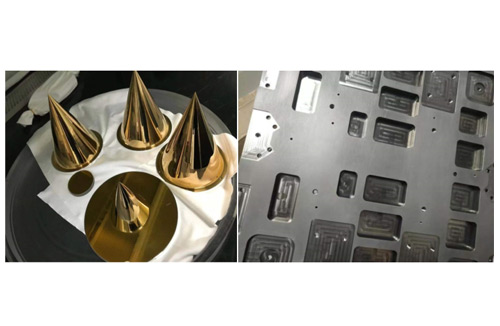

Considerable cost savings and lightweight packaging can be achieved by replacing copper/tungsten or copper/molybdenum with AlSiC in electronic packaging. It also has high thermal conductivity and low CTE values of 6.8ppm/C to 16ppm/C which is compatible with dielectric substrates, ceramic solder ball arrays (BGA), Low Temperature Sintered Ceramic (LTCC) materials and printed circuit boards. The high strength and stiffness also protect integrated circuit devices during assembly. Besides, the low density improves device reliability when subjected to shock or vibration. The geometry of the optoelectronic package is more complicated than that of the flip-chip cover, so more precise size control is required for the optical alignment pattern. All packages are molded and no additional processing is required. Hence lower cost compared to conventional packages. Thermal management in optoelectronic devices is also very important. Devices need to operate around room temperature, which requires materials with good heat dissipation properties to maintain temperature uniformity and optimize cooler performance. The tunable matched CTE values of the metal matrix composites can ensure the alignment of sensitive optics during operation, while also eliminating residual stresses that may be introduced during soldering or brazing assembly.

◆AlSiC lids have simple shape and structure, but super heat dissipation capacity.

◆AlSiC lids have the matching thermal expansion coefficient with different substrates and high thermal conductivity.

◆AlSiC lids have excellent high temperature stability and uniformity.

◆The surface can be plated with nickel, gold, silver, copper with good plating performance.

Application: It can be used for electronic chips (application-specific integrated circuits) and power modules, or microprocessor lids.