| Company |

Flexural strength (Mpa) |

Yield strength (Mpa) |

Density (g/cm3) |

Thermal Expansion (CTE ppm/℃) |

Thermal Conductivity (W/mK) |

| SITRI | 393 | 241 | 3.00 | 7.35 | 223 |

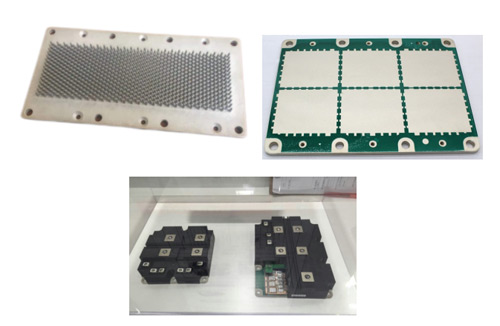

AlSiC can match the aluminum nitride CET value of the IGBT, effectively solving the problem of failure of the solder joints between the copper substrate and the ceramic bracket under high-power cycling conditions.

◇The low CTE perfectly matches with that of semiconductor chips and ceramic substrates.

◇AlSiC modules work well after tens of thousands of thermal cycles.

◇high thermal conductivity of min 180 W/mK @25℃

◇The lowest density of AlSiC is 2.95g/cm³, which is only 1/3 of copper’s.

◇High strength and hardness of AlSiC can improve device reliability when subjected to mechanical shock or vibration.

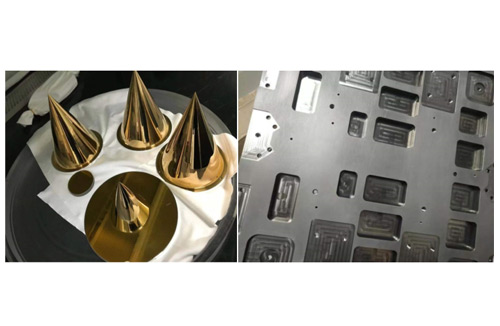

◇Chips can be soldered on the flat side of the substrate, and heat sink connected to the arch one.

◇The surface can be plated with matte nickel, bright nickel, etc.

◇It can be used as solder mask after plating.

Application: Used in IGBT baseplates for high power applications, including motor controllers for high-speed electric trains, hybrid and electric vehicles, subway cars, and wind turbines.