The Packaging-level thermal Solution is mainly aimed at the thermal design of electronic template and the PCB circuit board. It is closely related to the circuit design and structural design of the equipment. It’s about the selection of circuit board substrates.

Metal Matrix Ceramic Base Plate

1. Density is between 2.95-3.05g/ cm³;

2. The thermal expansion system (CTE) is between 6-9ppm/℃, and the thermal conductivity is 180-240(W/mK).

3. It has the adjustable volume fraction; Increasing the volume fraction of SiC can significantly reduce the thermal expansion coefficient.

4. With high thermal conductivity and specific stiffness;The surface can be plated with nickel, gold, silver, and copper with good plating performance.

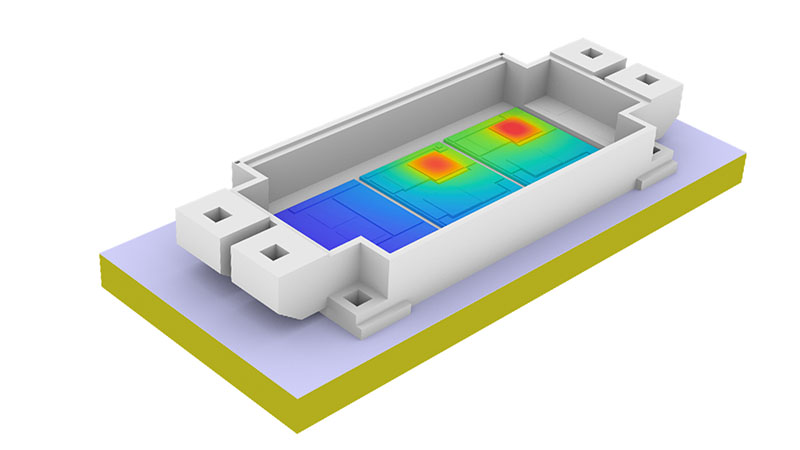

Ceramic Base Plate

1. The CTE of the ceramic base plate is close to that of the silicon chip, which can save the use of Mo interlayer, also saving the labor and material cost.

2. With thinner welding layer and lower thermal resistance, the ceramic baseplate will improve the yield.

3. Excellent thermal conductivity makes the chip package very compact, so that the power density is greatly improved, and also the reliability of the system or device; The high Insulation Voltage ensures personnel and equipment safety.

4. Ultra-thin (0.25mm) ceramic substrates can replace BeO, non-toxic and environment friendly; It can also realize the new packaging methods, making products highly integrated and compact in size.

5. Large carrying capacity; 100A current continuously passes through the 1mm wide 0.3mm thick copper body, the temperature rise is about 17℃; Through the 2mm wide 0.3mm thick, the temperature rise is only about 5℃.

6. Low thermal resistance; Taking a 10×10mm ceramic substrate as an example, the thermal resistance of 0.63mm thickness is 0.31K/W, the thermal resistance of 0.38mm thickness is 0.19K/W, and the thermal resistance of 0.25mm thickness is 0.14K/W.

Metal Base Plate

Metal base plates have been increasingly used in the fields of hybrid integrated circuits, automobiles, high-power electrical equipment, and power supply equipment, due to its excellent performance of heat dissipation, machining, electromagnetic shielding, dimensional stability and magnetism etc., especially as a base substrate in LED packaging products.

1.The metal base plate can effectively dissipate heat, thereby alleviating the problem of thermal expansion and contraction of different components on the circuit board, and improving the durability and reliability of the whole machine and electronic equipment.

2.Many double-sided and multi-layer boards have high density and high power, and it is difficult to dissipate heat. Conventional circuit board substrates such as FR4 and CEM3 are poor conductors of heat. They are insulated between layers and cannot dissipate heat, resulting in high temperature failure of electronic components. Metal-based printed boards can solve this problem.

3.The size of the metal substrate is obviously much more stable than that of the insulating material.

4.Iron substrate, with shielding effect, can replace brittle ceramic substrate, replace components such as radiators, improve product heat resistance and physical properties, and reduce production costs and labor.