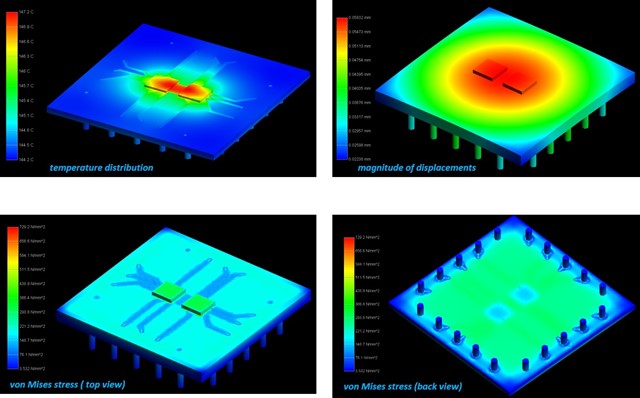

The electronic equipment is composed of components of various materials with different thermal expansion coefficients, such as silicon chips, silicon oxide insulating films, aluminum interconnect lines, metal lead frames and plastic packaging shells. Once the temperature changes, a compressive or tensile stress will be generated on the interface of different materials, thus resulting in thermal mismatch stress. The mismatch of thermal properties of materials is the internal cause of thermal stress, and the temperature change is the external. Component-level thermal design is to prevent device failure due to overheating or alternating temperature.

At present, most components use the third-generation electronic packaging materials represented by AlSiC, AlSi, diamond/copper and diamond/aluminum as the substrate.

1. Its CTE can be matched with dielectric substrates, ceramic ball arrays (BGA), low temperature sintered ceramic (LTCC) materials, and printed circuit boards, and it also has high thermal conductivity. High stiffness also provides protection for integrated circuit devices during assembly. The low density of such materials also improves device reliability when subjected to shock or vibration.

2. The geometry of the optoelectronic package is more complicated than that of the flip-chip cover, so more precise size control is required for the optical alignment pattern. All packages are molded and no additional processing is required for critical optical alignment parts. Hence lower cost compared to conventional packages. Thermal management in optoelectronic devices is also very important. Devices need to operate around room temperature, which requires materials with good heat dissipation properties to maintain temperature uniformity and optimize cooler performance. The tunable matched CTE values of the metal matrix composites can ensure the alignment of sensitive optics during operation, while also eliminating residual stresses that may be introduced during soldering or brazing assembly.